-

What's In Your Box

- History, Trusted Brands & Training

- Manufacturing, Engineering & Testing

- ABS Speed Sensors

- ADAS

- Blower Motor Resistors

- Camshaft & Crankshaft Sensors

- Collision Repair Program

- Electronic Throttle Bodies

- EV / Hybrid Program

- EVAP Components

- Gas Fuel Injection

- GDI Injection

- Ignition Coils

- NAPA Echlin Import Coils

- NAPA Echlin Kits

- Oil Filter Housing Kits

- Oil Pressure Switches

- Parking Brake Actuators

- TPMS

- Turbocharger Kits

- Variable Valve Timing

- Resources

- Gaskets included for a complete repair, where required

- 100% NEW, never remanufactured and 100% calibrated and tested

- NAPA® Echlin® is proud to offer a line of ETBs that includes 200+ SKUs covering 190M+ VIO

NAPA® Echlin® Premium ETBs Are 100% NEW, Never Remanufactured

As an expert Electronic Throttle Body manufacturer, we maintain complete quality control throughout the entire manufacturing process. We assemble and calibrate the components and validate output voltages to ensure they match OE for fit, form and function. NAPA® Echlin® ETBs are application-specific and precision-engineered for the units they are replacing.

What’s inside the NAPA® Echlin® box... improved gear trains, extensive testing and nearly 100 years of experience. What’s in your box?

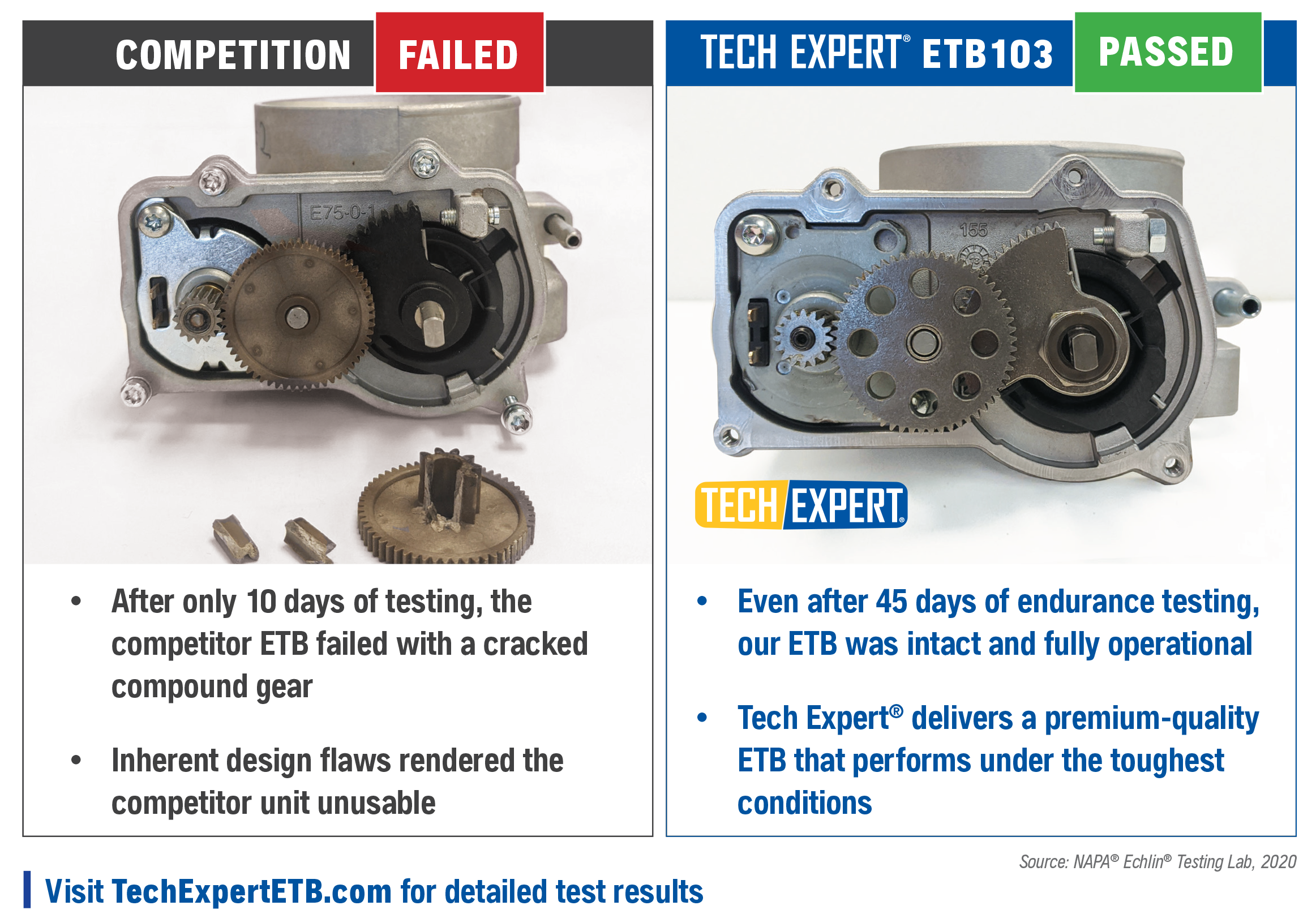

ETBs have high OE failure rates, and most are caused by a failure in the gear train. NAPA® Echlin® engineers review OE weak points and update the geometry and materials (when necessary) for a longer-lasting ETB.

Optimal Performance Begins with Quality Components

-

Gasket included where required

-

All NAPA® Echlin® manufactured ETBs are built in our North American IATF 16949-certified facility

-

Undergoes extensive testing to ensure quality and reliability out of the box

-

Custom elastomeric seal protects sensor from environmental underhood elements such as dust, vapor and liquids

-

As a basic manufacturer, NAPA® Echlin® engineers upgrades to failure-prone OE components

-

New, never remanufactured, which maximizes performance and extends service life

-

100% calibration and testing ensure superior performance and durability

-

Magnet molded in high-performance polymer to ensure consistent location and low friction with bearing surfaces

Our ETBs Are the Result of Superior Design, and the Testing Proves It

NAPA® Echlin® Electronic Throttle Body’s superior quality stands up to the most severe underhood conditions and strenuous demands of today’s engines. The competition did not.

For nearly 100 years, when the OE failed, technicians have trusted NAPA® Echlin® to deliver a part that’s equal to or better than the original it’s replacing.