NAPA Echlin Heavier-Duty Ignition Coils

NAPA Echlin’s new heavier-duty ignition coils are the product of superior design, manufacturing, and testing. See below how our NAPA Echlin Heavy-Duty Coil compares to the OE.

Product of Superior Design

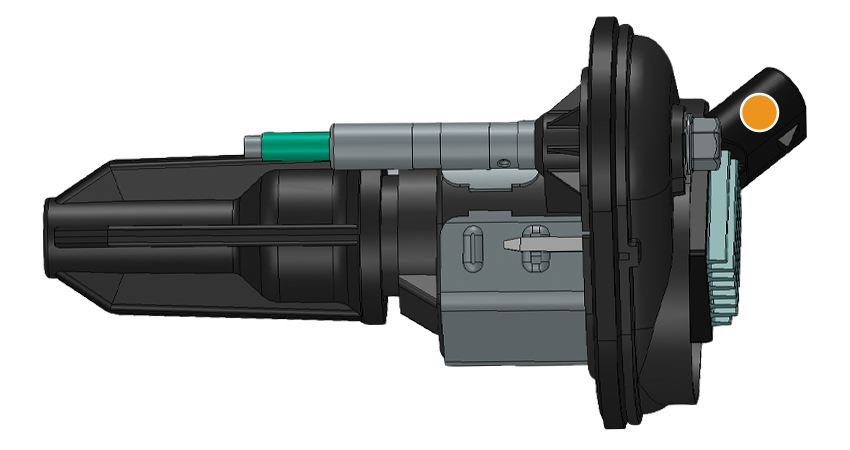

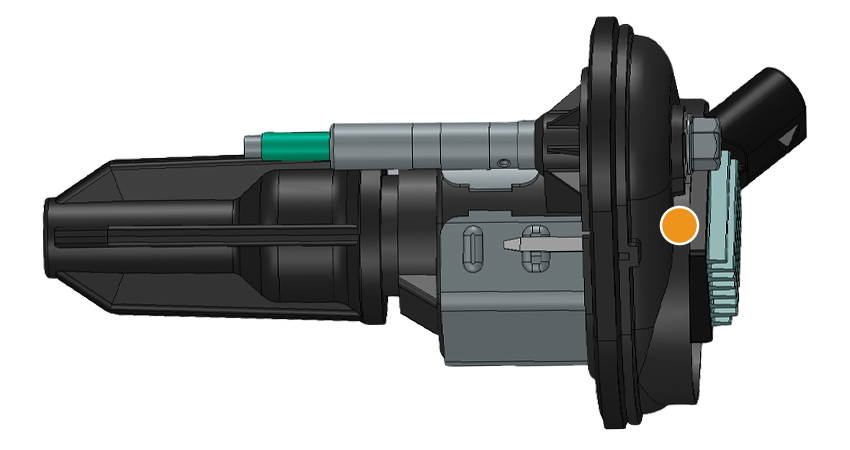

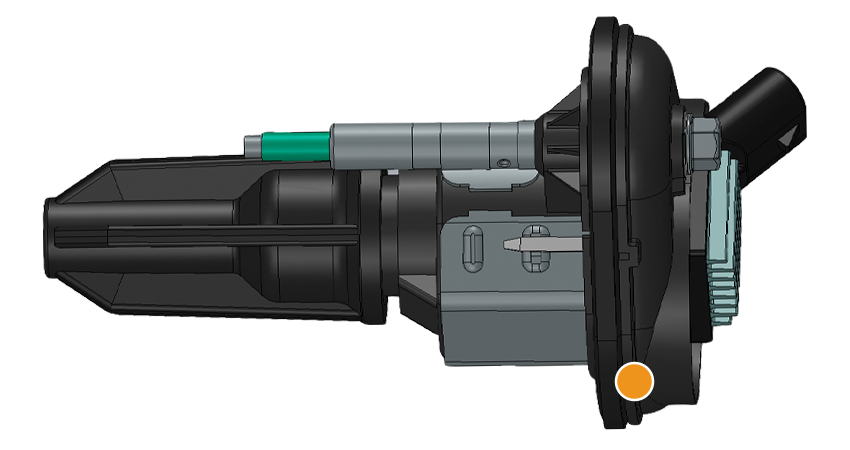

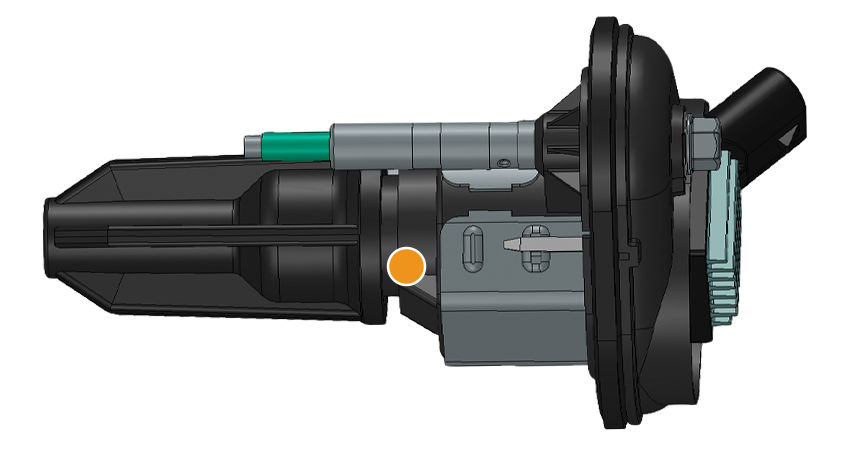

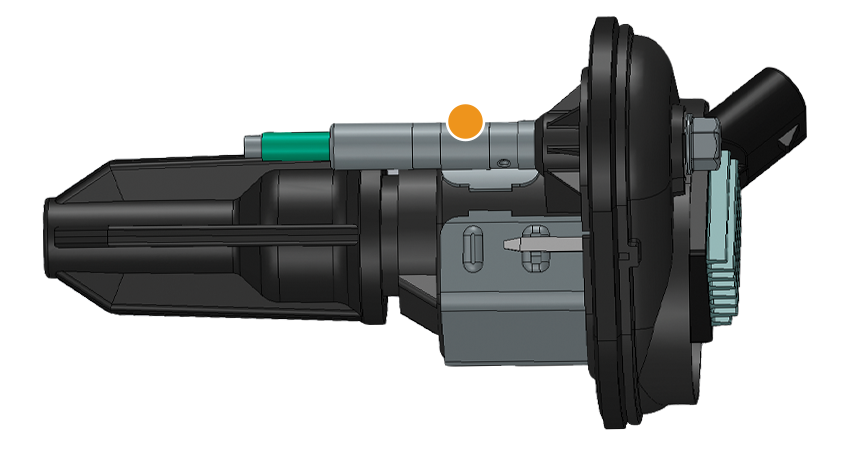

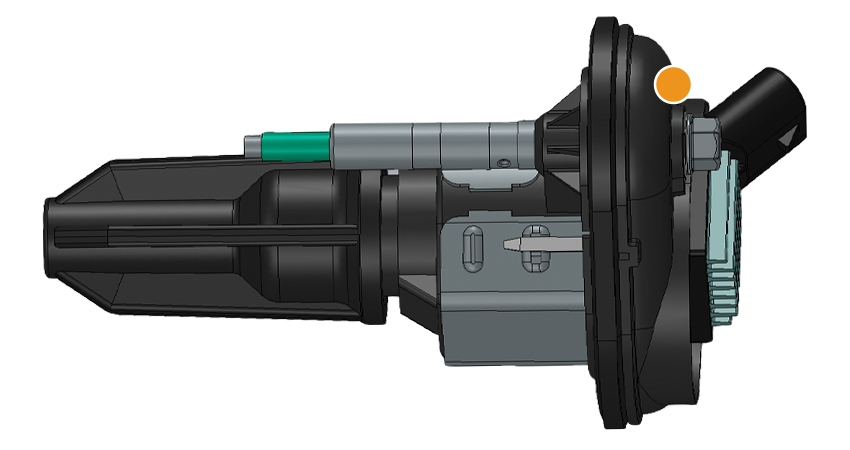

NAPA Echlin’s new heavier-duty ignition coils are the product of superior design, manufacturing, and testing. For example, take our IC414, one of the many new heavier-duty ignition coils in our line.

-

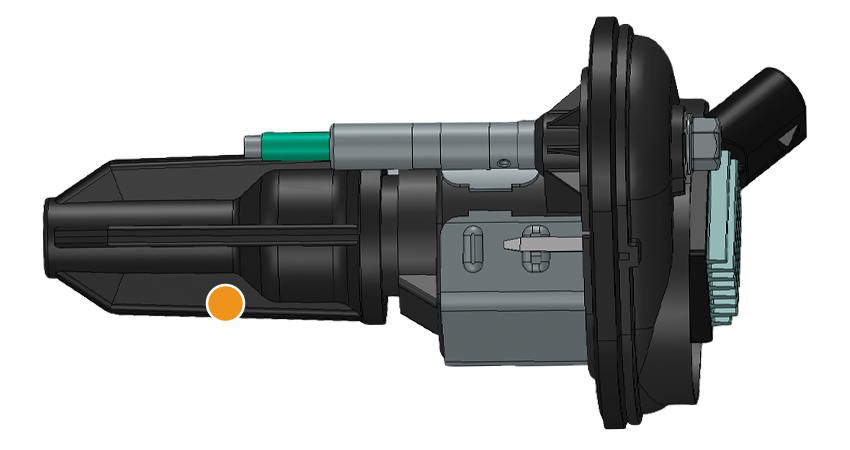

Advanced thermoplastic coil connector ensures proper connection and resists fractures caused by heat and thermal cycling

-

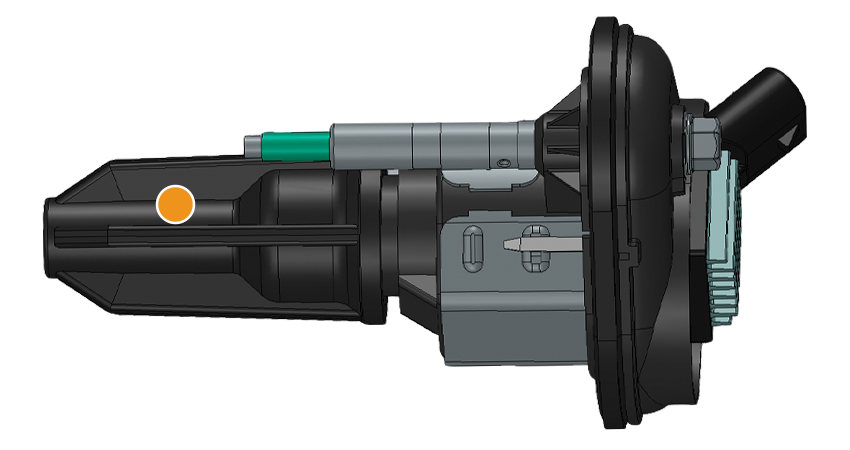

Primary (23 gauge) and Secondary (43 gauge) copper wire ensure high-voltage availability for peak performance while reinforced bobbins prevent voltage flashover for extended service life

-

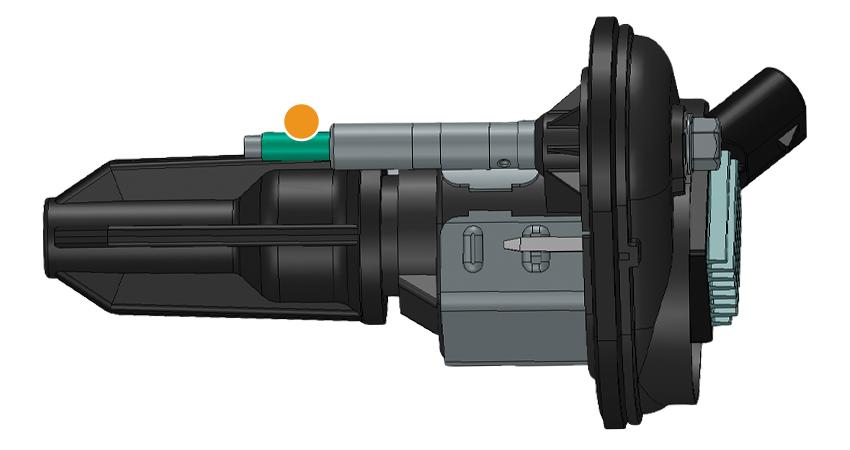

High-impact housing material ensures superior bond to epoxy for longer life in all operating conditions

-

Internal, neodymium permanent magnet core surrounded by grain-oriented, magnetic-laminated steel maximizes high-voltage output at all engine RPMs and loads

-

Tested at extreme engine performance condition at 7200 RPM

-

Engineered and tested to match or exceed OE for spark energy output, impedance, and durability

-

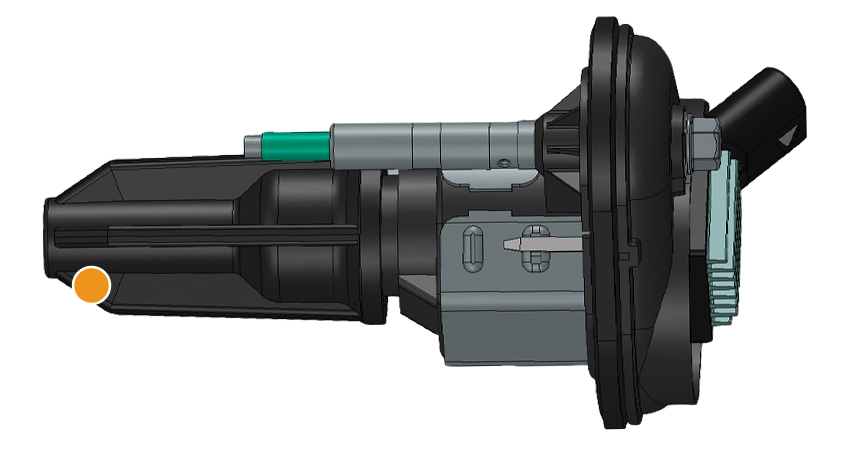

High-temp boot prevents high-voltage leaks, while stainless-steel spring with internal ferrite noise suppressor prevents radio frequency interference (RFI)

-

Isolator manufactured using high voltage-resistant thermoplastics to prevent premature coil failure

-

Copper wires using higher insulation grade ensure heat resistance and prevent high voltage breakdown

-

Optimum wire distribution developed by extensive testing ensures superior functional parameters and durability